Design Office - 3D additive manufacturing - Projet monitoring in industrial methods

ABOUT

Office design and projets in indutrial methods. Specialized in 3D additive manufacturing, Machining, Forging, Fondry,Injection...

You are in business overload?

You outsource studies, manufacturing, industrial engineering projects.

You want to optimize your industrial process ?

You outsource studies, manufacturing, industrial engineering projects.

You want to optimize your industrial process ?

Benefit from our expertise in manufacturing and industrial methods, develop new ideas and exploit other manufacturing processes for your products. We design and manufacture your custom workstations ans equipement

Installed in Brittany west of Rennes, between two major roads (N12, N24).

We operate in the West and throughout France for multi-sectoral markets.

We operate in the West and throughout France for multi-sectoral markets.

Transportation - Energy - Agri-Food - Products and Capital Goods - Industrial Subcontracting

From start-ups to large industrial groups.

From start-ups to large industrial groups.

OUR MISSION:

We adapt and design your products according to your specifications and we offer you the most suitable manufacturing process.

We take care of the manufacture of your products, until their controls and good to deliver.

In the case of injected parts, forgings, castings, we take care of the design as well as the manufacturing of the tools at our partners until the delivery of the initial samples.

We adapt and design your products according to your specifications and we offer you the most suitable manufacturing process.

We take care of the manufacture of your products, until their controls and good to deliver.

In the case of injected parts, forgings, castings, we take care of the design as well as the manufacturing of the tools at our partners until the delivery of the initial samples.

OUR VALUES:

LISTENING - COUNSELING - RIGOR - CREATIVITY - IMAGINATION

Our professional conscience, listening and counseling are at the center of our concerns.

Rigor and organization are the strength of our creativity and imagination.

We adapt to your constraints to follow your objectives and go towards the reliability cost and delay.

We manage projects with responsibility and respect for confidentiality.

Rigor and organization are the strength of our creativity and imagination.

We adapt to your constraints to follow your objectives and go towards the reliability cost and delay.

We manage projects with responsibility and respect for confidentiality.

ECO-CONCEPTION - RECYCLATIBILITY

Although industrial, we seek to reduce our impact on the environment by promoting eco-design and maximizing recyclable or bio sourced materials..

our partners

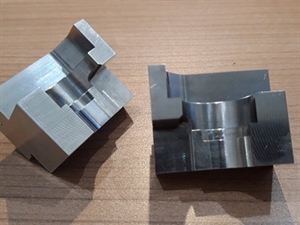

IdPROD and Pro-G2i pool their resources to offer their customers the entire value chain.

IdPROD is specialized in the machining of unit parts, prototypes and small series.

IdPROD is specialized in the machining of unit parts, prototypes and small series.

DONNONS DU SENS is the Brittany agency that supports companies towards the circular economy through eco-design.

Pro-G2i acts as a business consultant.

Pro-G2i acts as a business consultant.

DONNONS DU SENS is the Brittany agency that supports companies towards the circular economy through eco-design.

Pro-G2i acts as a business consultant.

Pro-G2i acts as a business consultant.

DONNONS DU SENS is the Brittany agency that supports companies towards the circular economy through eco-design.

Pro-G2i acts as a business consultant.

Pro-G2i acts as a business consultant.

Initiative Brocéliande, the RENNES CCI and its Antenne A3C, trust us and support us.

OUR mISSION

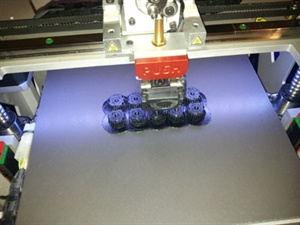

3D ADDITIVE MANUFACTURING

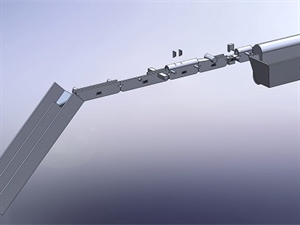

We highlight the design and manufacture of mechanical parts in 3D additive manufacturing for the general mechanical industry and precision.

We are sure of the development opportunities offered by 3D additive manufacturing for precision mechanical metal and polymer parts and will explore with you the solutions provided by this innovative technique, such as:

We are sure of the development opportunities offered by 3D additive manufacturing for precision mechanical metal and polymer parts and will explore with you the solutions provided by this innovative technique, such as:

PRODUCTS ALLEVIATION - ASSEMBLIES REDUCTION - OBSOLESCENCE PARTS DUPLICATION

PRODUCT CUSTOMIZATION - ADDED THERMAL CHANNEL OR REGULATIONS - MOULD CAVITY

The 3D additive manufacturing is not suitable for all parts configurations so our 20 years of expertise in the metal and polymer processing industry, allows us to take charge of your studies, the monitoring and manufacturing of your single, small, medium series parts with traditional manufacturing processes such as:

MACHINING - FORGING - FOUNDRY - INJECTING - CUTTING - ASSEMBLY

We have knowledge of many materials (Steel, Brass, Aluminum, Zamak, Polymer ...) and the associated treatments and coatings, we will guide you !

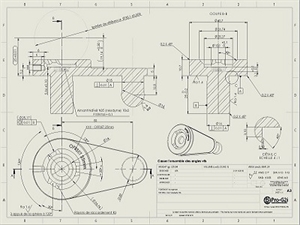

STUDies And innovations

Design of the product - Definition of specifications - Value analysis and functional

ECO-CONCEPTION - A.M.D.E.C - Digital 3D CAD modeling - Prototypes and models

Follow the phases of industrialization until homologation ;

ECO-CONCEPTION - A.M.D.E.C - Digital 3D CAD modeling - Prototypes and models

Follow the phases of industrialization until homologation ;

From the expression of the functional need to the approval of the initial samples:

Design of the product - Definition of specifications - Value analysis and functional

ECO-CONCEPTION - A.M.D.E.C - Digital 3D CAD modeling - Prototypes and models

Follow the phases of industrialization until homologation ;

ECO-CONCEPTION - A.M.D.E.C - Digital 3D CAD modeling - Prototypes and models

Follow the phases of industrialization until homologation ;

Our business expertise allows to design a product optimized technically and economically.

Knowledge of many manufacturing processes and manufacturing tools:

Knowledge of many manufacturing processes and manufacturing tools:

3D additive manufacturing - 3D printing - Machining

Stamping - Casting - Cutting fine sheet metal.

Injecting : Aluminum, Zamak - Plasturgy: Injecting

Treatments of materials - Surface coatings.

Stamping - Casting - Cutting fine sheet metal.

Injecting : Aluminum, Zamak - Plasturgy: Injecting

Treatments of materials - Surface coatings.

Knowledge of the complete cycle of mechanical development allows us to optimize, make reliable and anticipate each phase, in compliance with cost-time commitments.

Our customers also have access to our suppliers-partners address book.

Our customers also have access to our suppliers-partners address book.

MANUFACTURING

Prototypes, mechanical parts manufacturing and mechanical assembly:

Machining - 3D additive manufacturing - 3D printing - Treatments and surface coatings - Assembly.

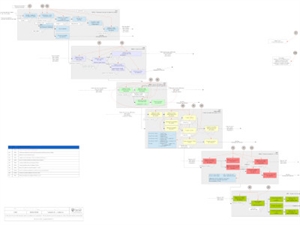

Follow-up of industrial projets

Follow-up of industrial projects :

Production tools :Injecting mold;cutting tool.

Production equipment: Automatic or manual assembly stations; METROLOGY and LABORATORY equipment.

Continuous improvement: 5s ou 6s; SMED; Lean Manufacturing.

Production equipment: Automatic or manual assembly stations; METROLOGY and LABORATORY equipment.

Continuous improvement: 5s ou 6s; SMED; Lean Manufacturing.

We accompany you, with our partners, until the homologation of the tooling and the initial samples. In a partner structure or in your industrial site.

We can also use the partners you have qualified. We will integrate them from the beginning of the project to allow us to accurately anticipate the costs and delays of the serial manufacturing processes.

For the manufacture of your tools and the production of your parts, we consult our partners in Brittany, France or Europe.

We can also use the partners you have qualified. We will integrate them from the beginning of the project to allow us to accurately anticipate the costs and delays of the serial manufacturing processes.

For the manufacture of your tools and the production of your parts, we consult our partners in Brittany, France or Europe.

CONTACT

Want to know more? Contact us by this form.

Conformity RGPD*

* By filling out this form, you consent to our collecting your data so that we can respond to your message. To assert your right of access or erasure, please consult our privacy policy.

send

.png)

.png)